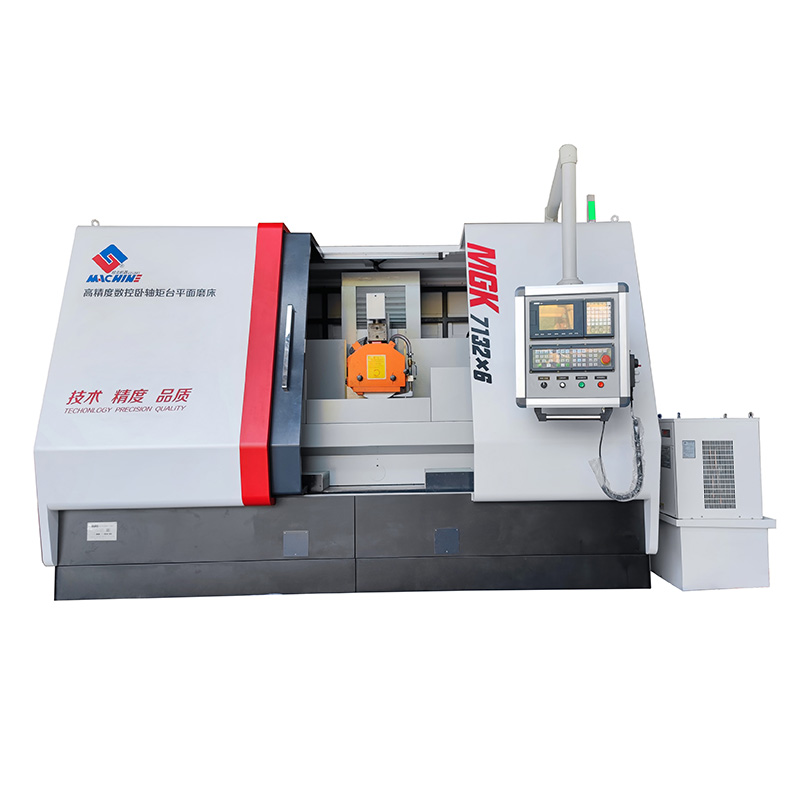

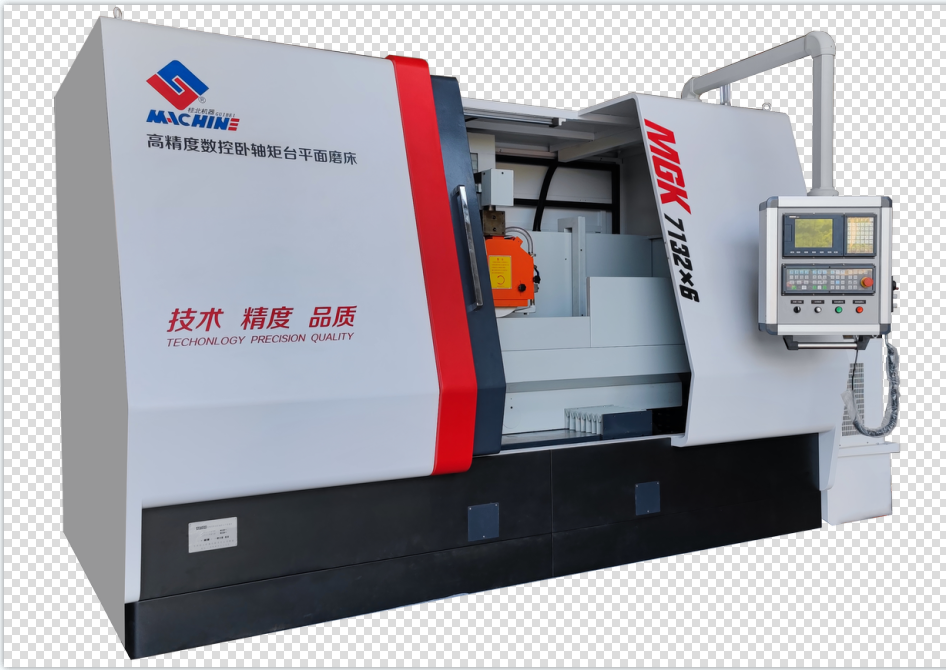

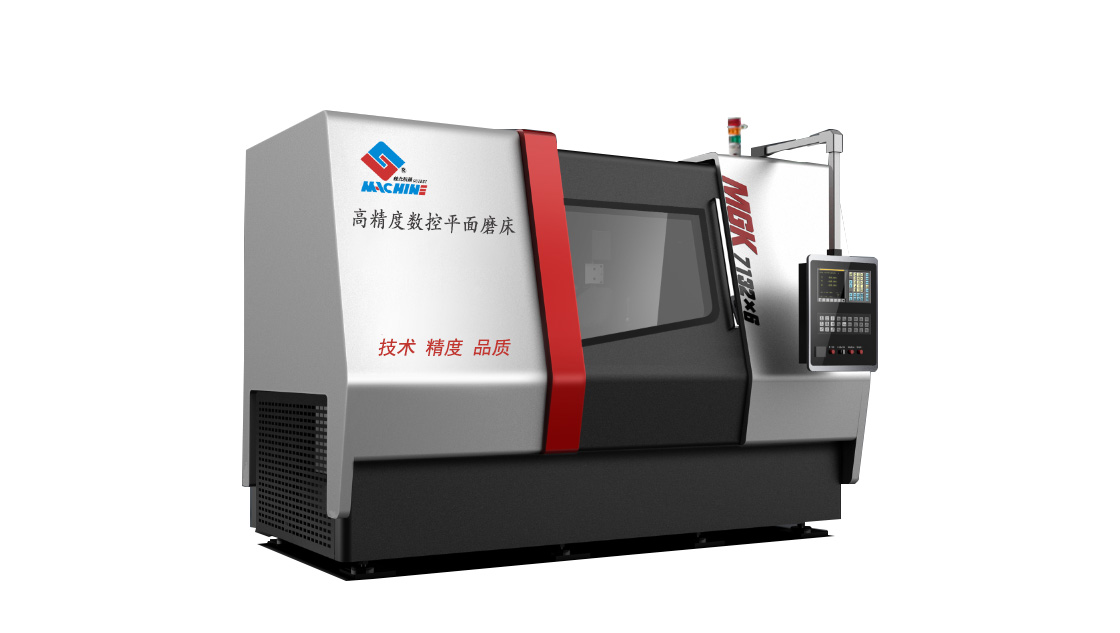

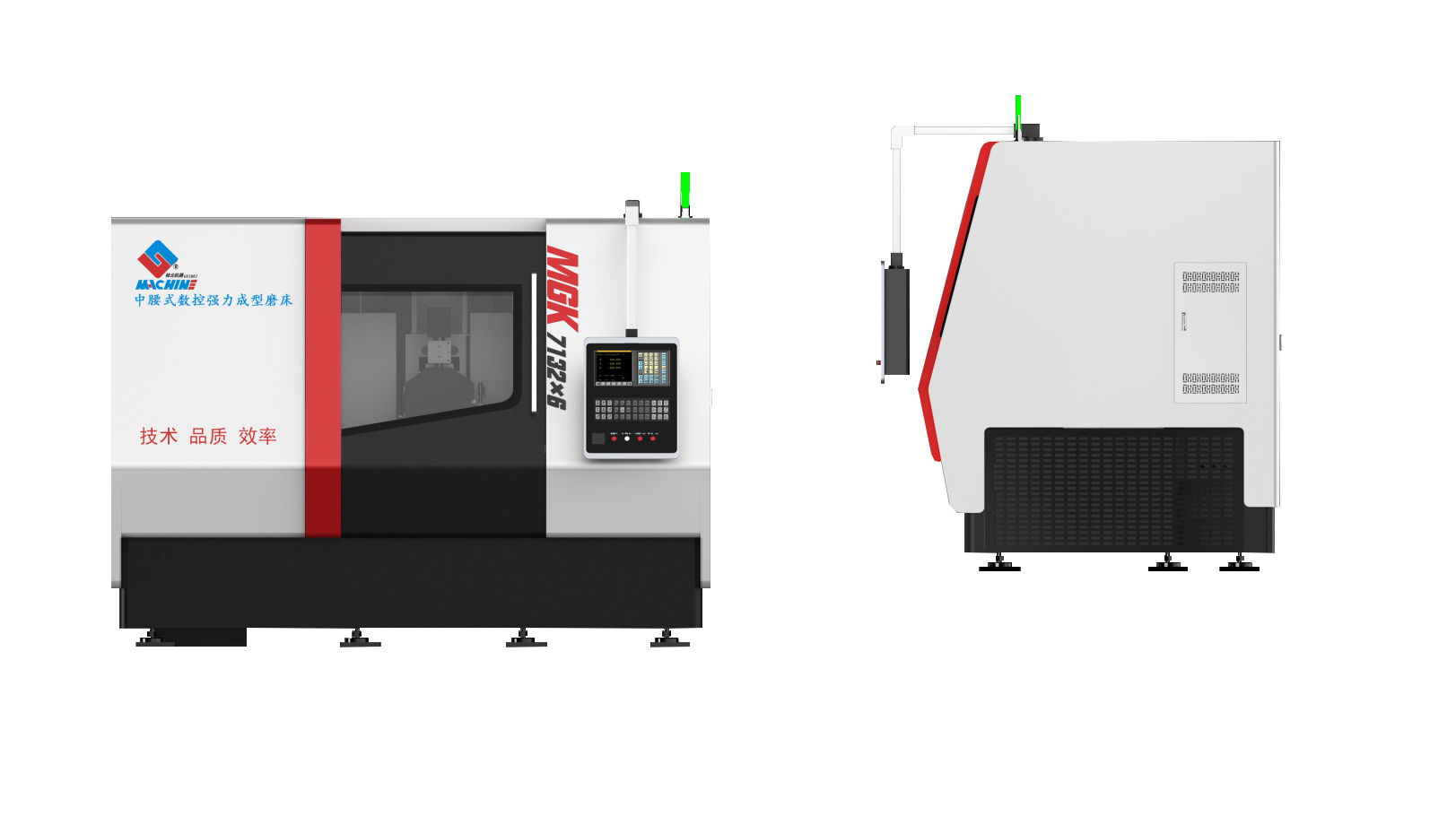

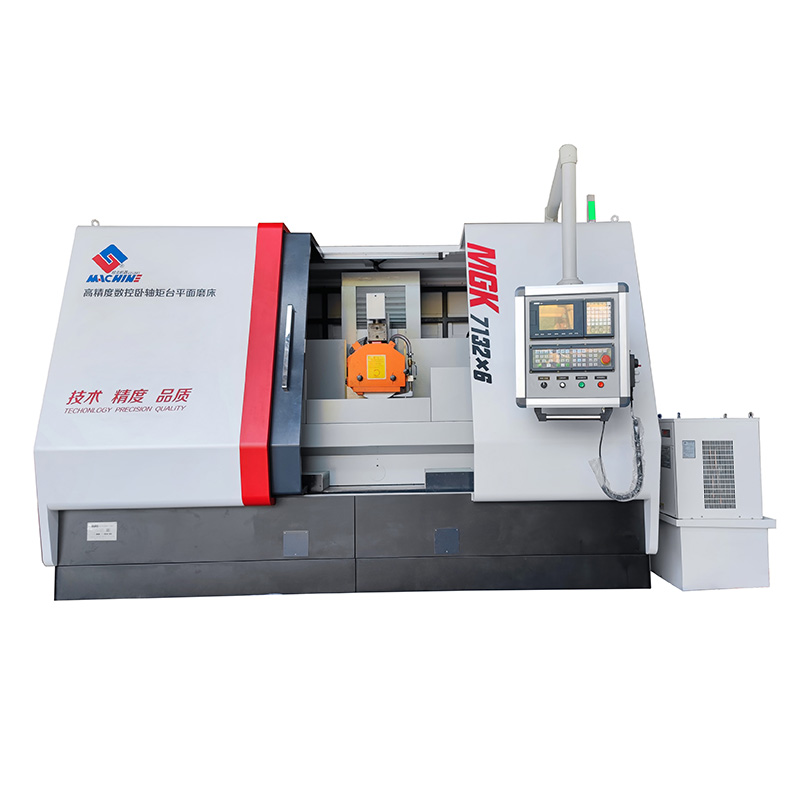

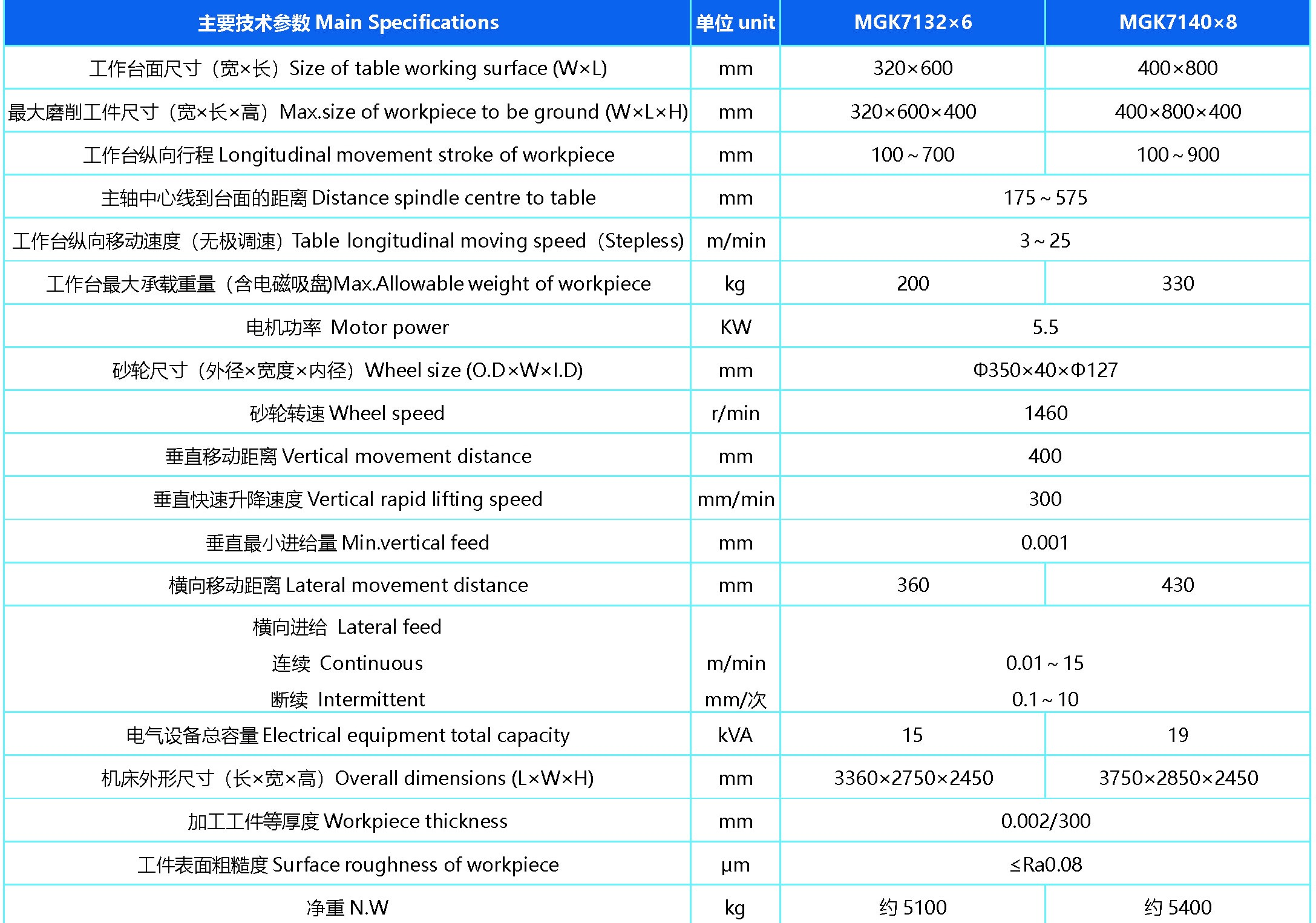

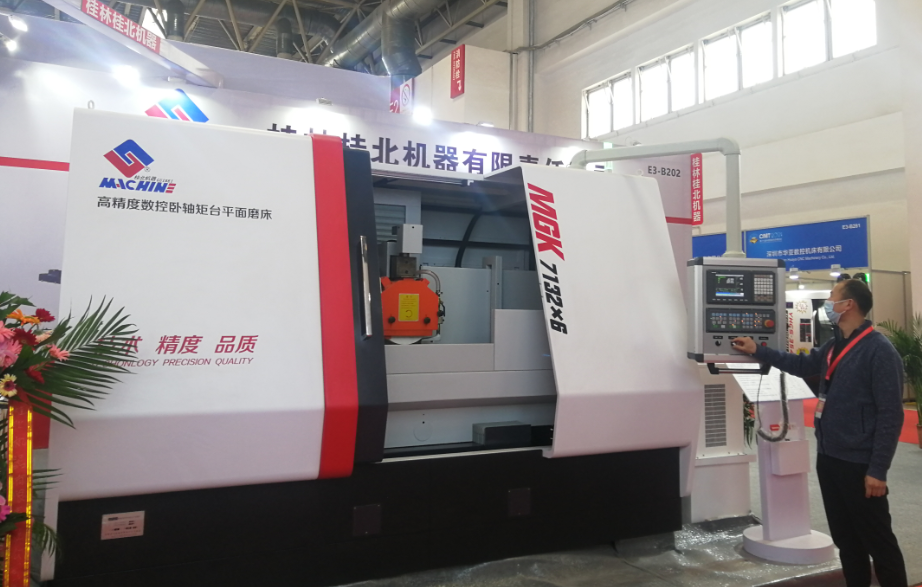

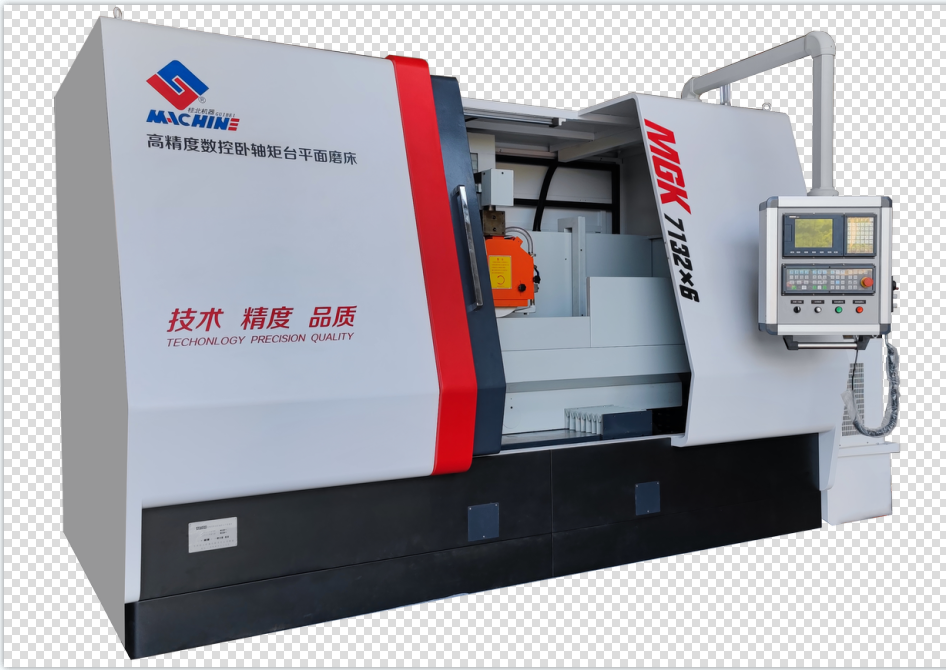

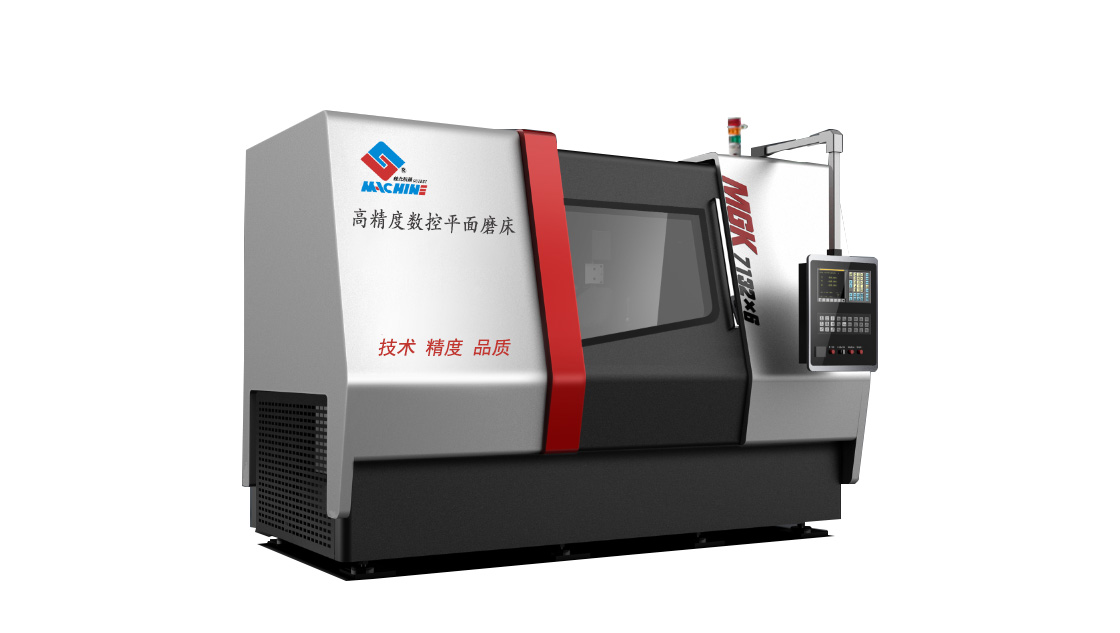

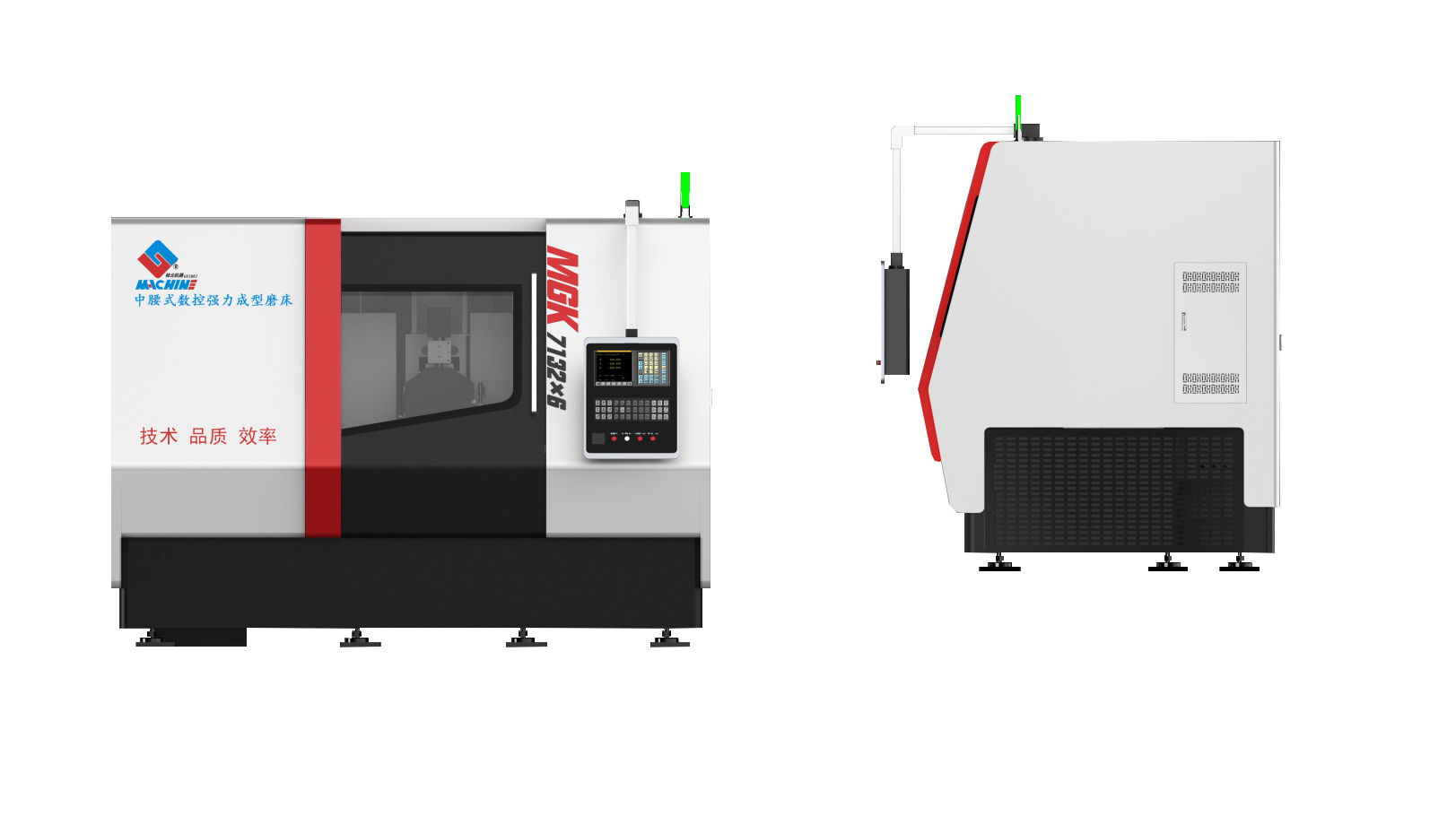

This series of products are high-precision surface grinders with a comprehensively upgraded appearance, suitable for grinding high-precision parts in equipment manufacturing, military industry, molds, automobiles, hydraulic components, optical instruments and other industries.

1. Adopting the mobile layout of the carriage, the machine tool has good stability and good heat retention.

2. The longitudinal movement of the worktable is driven by an external hydraulic station, and the thermal deformation is small.

3. The lateral movement of the carriage adopts the AC servo motor to drive the precision ball screw pair transmission. Small intermittent feed and low-speed continuous motion can be realized;

4. The vertical feed adopts the AC servo motor to drive the precision ball screw drive, and is used in conjunction with the precision needle roller cross guide rail pair, and the feed sensitivity is high.

5. The grinding wheel spindle adopts the structure of dynamic and static pressure bearing, which has high rotation precision and low surface roughness of the grinding workpiece.

6. The use of hydraulic-electrical joint control grinding wheel dresser can realize automatic and precise grinding wheel dressing.

7. The grinding wheel protective cover has the function of opening the door and powering off, which is highly safe.

8. Standard Taiwan new generation CNC system.