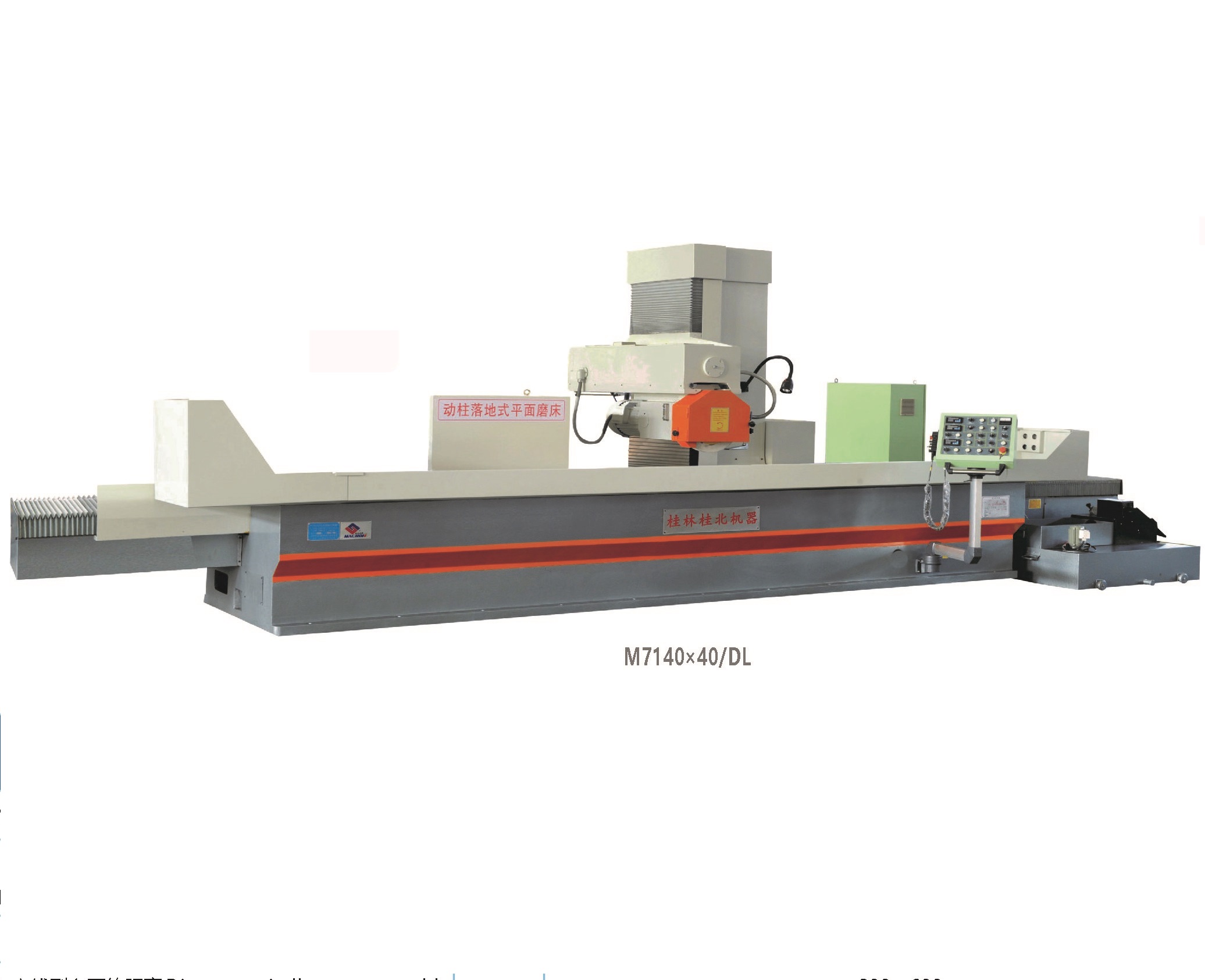

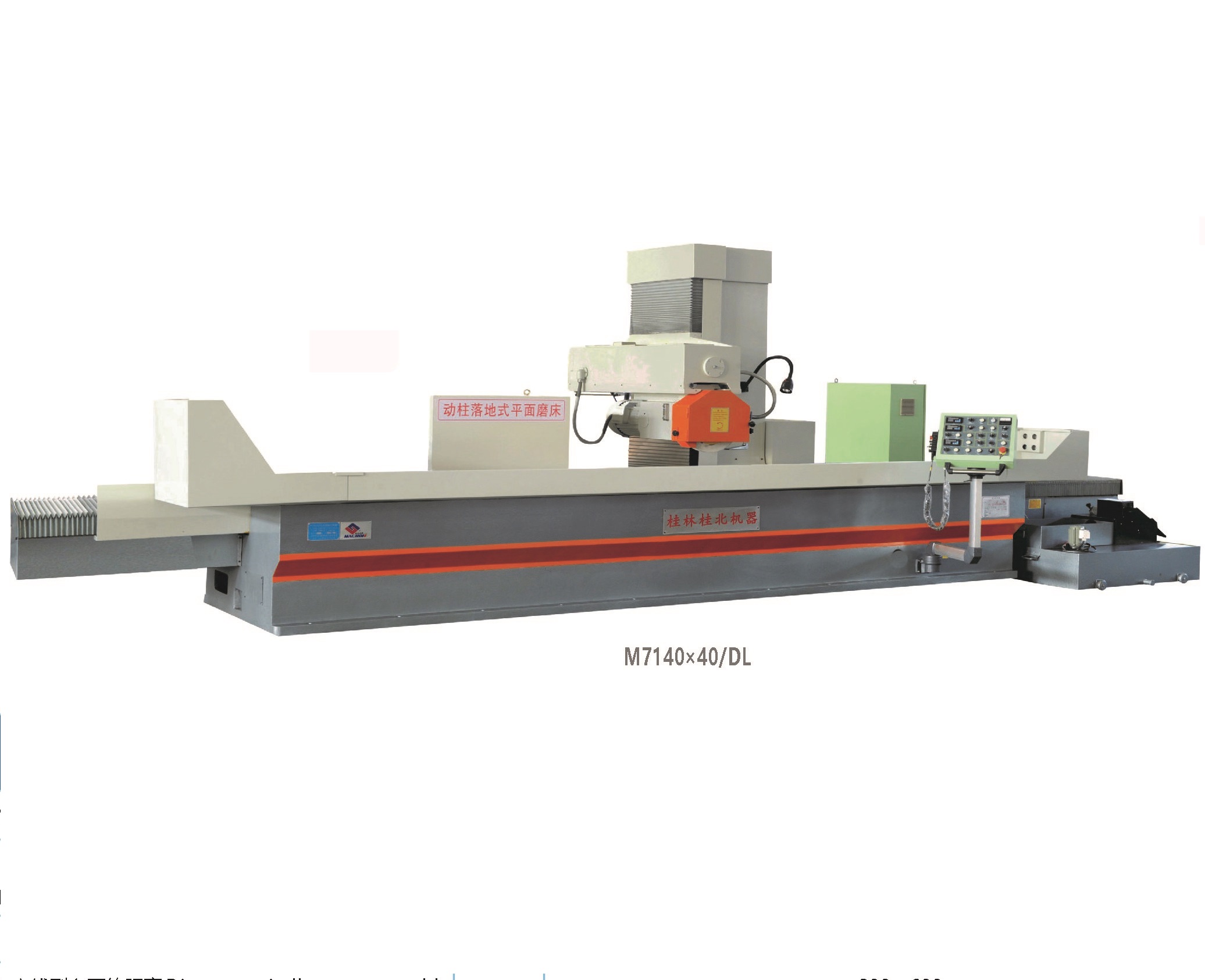

This series of machine tools adopts the structure of fixed table and longitudinal moving column, using the peripheral or end face of the grinding wheel to grind the surface of the workpiece, suitable for grinding the plane and side edges of various parts in the industries of machinery manufacturing, automobile, mold and die, and industrial measuring tools.

Features:

●The bed and table are integrated and the fixed floor structure layout is adopted, which reduces the floor space by more than one-third compared with the traditional structure and has a strong load capacity.

●The machine adopts AC servo motor driving precision ball screw transmission in three axes, with precise control.

●The longitudinal movement cancels the large-capacity oil tank, green manufacturing, energy-saving and environmental protection, greatly reducing the use and maintenance costs.

●The longitudinal guideway is fully lubricated by oil immersion to improve the service life of the guideway.

●The vertical guide adopts large span, wide and thick rectangular sliding guide, which has good anti-vibration effect and strong rigidity.

●The front end of the grinding wheel spindle adopts integral internal column and external tapered sliding bearing, with strong structural rigidity, high load capacity, good workpiece grinding surface quality and easy maintenance.

●Special digital instrument (program control system is also optional) control, equipped with fixed electronic handwheel, with manual and automatic grinding functions, can set grinding process parameters by itself, easy to operate.